About CFSS & LSF

Consumable steels in construction systems are produced in two ways and are named based on the type of production method:

Hot Rolling Steel

Cold Formed Steel

Cold Formed steel structure system was widely used and expanded around 1946 after the publication of the first American Steel Association (AISI) criteria derived from academic research conducted at Cornell University.

The first building system is mainly used for buildings of medium and high levels. And the second system is used for short and medium buildings. Since cold formed steel is produced in the thickness range of 0.3 to 6 mm. Therefore, the application of this steel in buildings is divided into two types: steel with a smaller thickness (usually 1mm-3mm) is used in the construction of systems consisting of cold-rolled continuous steel frames called LSF (Light Gauge Steel Framing). Also known as Light Weight Steel Structure. Also, steel with a thickness range between 3mm to 6mm is used in the construction of cold steel structures (Cold Formed Steel Structure / Cold Formed Steel Framing).

LSF structures for Low rise building and Mid-rise building

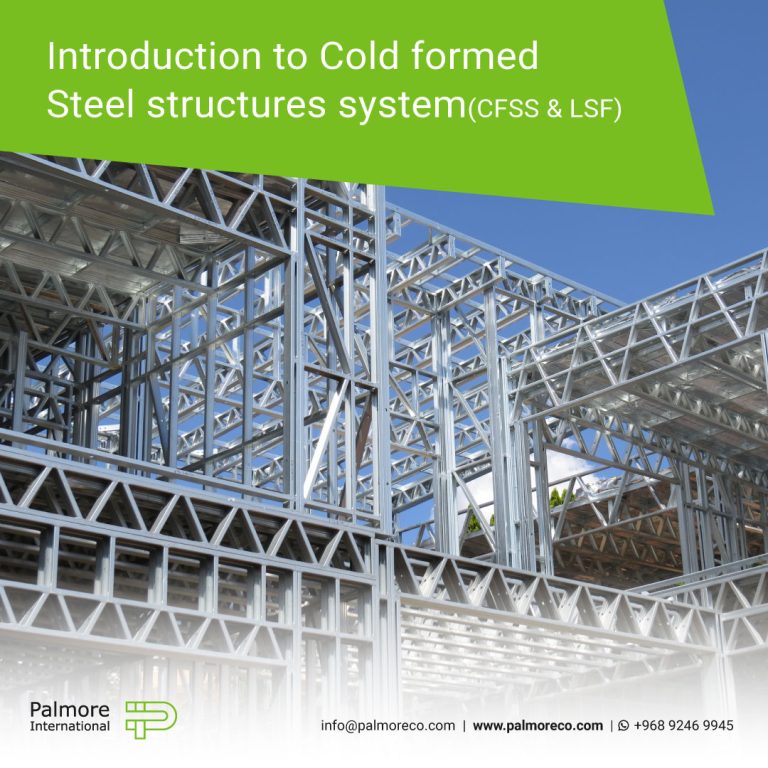

In this section, we are going to describe LSF structures:

“Familiarity and understanding of the performance of the construction system of chilled steel frames”

These types of structures show very good performance in terms of structural behavior. To understand more deeply the performance of this type of structure, it is not bad to first describe the performance of hot-rolled steel structures and then examine the performance of this type of structure.

Now we are going to explain the operation of these two types of systems with a simple example:

If we consider a two-story building consisting of cube-shaped rooms, if we use a hot-rolled steel skeletal system to build this building, we will have to use four relatively strong columns in the four corners of the rooms of this building, which are supported by vertical beams. They are connected to each other, which together form a two-tiered and interconnected steel frame.

In this system, the weight of the floors is transferred to the beams around the roof and the beams bend the force to the surrounding four pillars so that the load transfer path to the foundation and then the ground is completed. The walls in this type of system do not have a load-bearing role at all and will add to the load of the structure and are used only as a partition. It should be noted that the weight of the walls is transferred to the columns by the beam or the lower roof, and if there is no beam under the walls, only the load is transferred to the surrounding beams and finally to the columns through the function of the roof beams.

Now, if we want to use the Cold Formed Steel Structure system to build this simple building, we have to completely change our philosophy of thinking. In this type of system, the first question we have to answer. The location of the walls. In the above example, we will have a wall on all four sides. So instead of using only four columns, which allows us to transfer all the weight of the roof and walls to the ground through the main beams. Inside the walls, modularly, every 60 cm to 60 cm, we install a column. Four columns, in this system, the force is transmitted to, for example, 0 to 4 columns. As a result, the load-bearing capacity of each column is drastically reduced, in other words, each wall consists of a metal frame with a large number of columns, which is created by other orthogonal frames in the walls perpendicular to it, creating a complete three-dimensional system.

The steel consumption coefficient in this system, despite the large number of columns and structural elements, is much lower than hot-rolled steel structures, which leads to the economics of the project. In this type of system, the amount of steel consumed is between 27 and 35 kg per square meter. While in the hot rolling steel skeletal system, this amount is between 75-120 kg per square meter.

One of the important advantages of cold formed steel structures is a very high degree of uncertainty, which leads to a very good stability of this complex. While in hot rolling steel, the destruction of one of the columns can even lead to the destruction of the entire system. While in this system, due to the high number of columns, if some of them are destroyed, there is a possibility of load transfer by other columns.

The design and operation mechanism of this type of system is similar to timber structures (Timber Structure) and in countries such as the United States, which due to the large number of renewable forests, there is a lot of suitable wood for the structure of this type of structures due to economic efficiency as a system. Common construction of short and medium buildings is used. The use of Cold Formed Steel Structure is the best choice for low and medium rise buildings.This manufacturing technology replaces traditional manufacturing methods with common mistakes.

Cold Formed Steel Structure and Timber Structure

The method of execution of Cold Formed steel structures (LSF & CFSS) is based on drywall systems, which is the result of the idea of achieving a technology based on a modular system, fast execution and fully industrialized. These structures are made of a frame Consisting of horizontal runner and vertical stud structural elements. As mentioned, the function of this system is the same as the load-bearing wall system, so these assembled frames are placed at the location of the walls according to the calculations made. Finally, Gypsum Board is used to cover their surface. He also used sound and heat insulation to provide the physics of the building.

Advantages of Cold Formed Steel Structure (LSF & CFSS)

The most ideal system in the world for Low rise and Mid-rise building

Ability to implement up to 5 floors independently and higher in combination

Accurate structural calculations using specialized software

Excellent performance against lateral forces of wind, storm and earthquake

High build quality compared to other building systems

High accuracy and incomparable in execution of details

High diversity and flexibility in architectural design and interior design

Has all energy saving standards

Strength, safety, durability, high degree of uncertainty and excellent building reliability

Increasing the useful space inside the building compared to conventional steel structures

Fire resistant in accordance with all regulations of the world

Reducing the cost and ease of maintenance of the building compared to other methods

Completely economical with greater productivity and quick return on investment

Fast installation and execution speed, the ability to run in any operating conditions without stopping

Waste reduction, saving and optimal use of materials and manpower

Increase the useful life of the building and fully comply with the climatic conditions.

Industrial and modular production, reduction of ancillary costs and applicability in any difficult place

Ability to be used in the construction of new floors as well as the retrofitting of existing buildings

Ideal for mass production and the most desirable housing model option in developed countries

Ability to select and access quantities related to building physics (such as acoustic, thermal, and fire-retardant wall behavior)

Ensuring quality due to the possibility of step-by-step monitoring