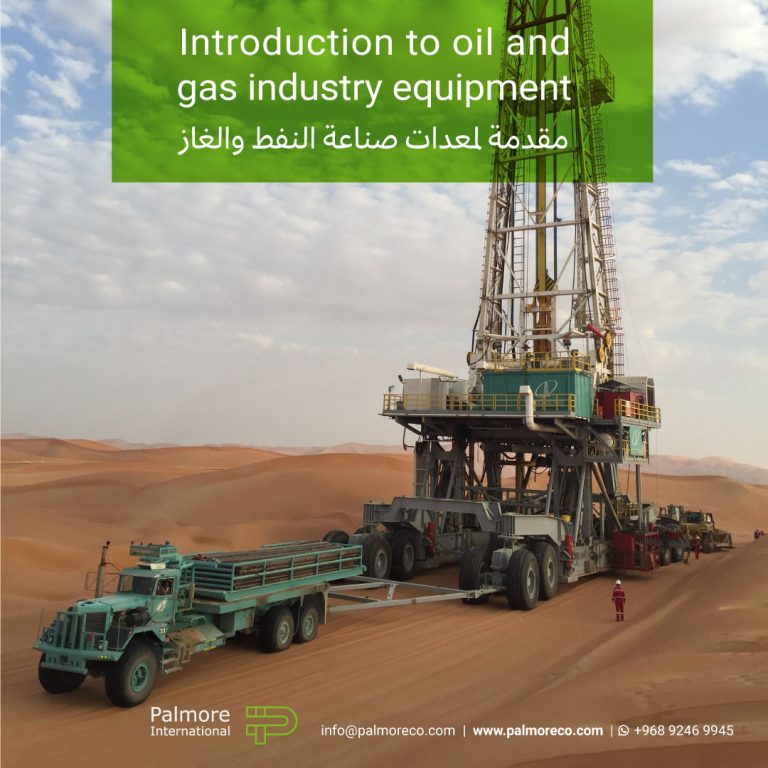

Introduction to oil and gas industry equipment

We need oil and gas industry equipment in refineries to convert these raw materials (oil and gas) into needed materials.

Oil and gas are among the most important sources of energy consumption in the world. Mankind had known about the existence of oil for centuries and used this oil in its raw form. But today, various materials such as kerosene, gasoline, diesel, bitumen, etc. are created through a process called refining, which are widely used and play an important role in the country’s economy.

In addition, they are used in fueling missiles, satellite carriers, etc., and need equipment for the oil and gas industry for this field. Natural gas is the cleanest fossil fuel. As a result, it reduces the harmful environmental effects of energy consumption in the world. It reduces human health by reducing pollutants such as nitric acid, sulfur oxide and other particles that are harmful to health. Natural gas is also used in transportation and conversion into liquid fuels. If mixed with diesel, it reduces pollution in cities.

All of this shows the importance of oil and gas in human life, but as we mentioned, these many resources are not usable in raw form and must be converted into needed materials in the refinery. To do this, we need oil and gas industry equipment in refineries. In the following, we will briefly explain the types of these equipments and their uses.

Equipment used in oil and gas industry

Carrying out the process of refining oil and gas requires special equipment that different companies are looking to build and produce the best and most efficient equipment. One of the most important points in the production of these products is the production of various alloys in the oil and gas industry equipment. Because they must be resistant to factors such as corrosion.

These equipments are used for items such as storage, transfer, heat control, flow control, etc. In general, oil and gas industry equipment is divided into two categories: rotary and fixed.

Rotating equipment with different speeds and modes such as reciprocating or rotating in motion and are used to process liquids in the system, which includes turbines, pumps, compressors, motors and gearboxes. But the fixed type, as its name implies, has no movement and includes the following:

Heat Exchangers

Piping

Storage tanks

valve

Pressure reducer

boiler

Furnace and heater

pipelines

All equipment should be designed according to the location used and the device should be inspected and controlled to ensure safety and proper operation. In this article, we will give a brief description of fixed equipment.

The role of heat exchangers in oil and gas industry equipment

The job of these converters is to receive heat and reuse it. Simply put, consider a tube containing cold liquid surrounded by hot liquid. As the liquid passes through the tube, the heat of the external fluid is transferred to the cold liquid and vice versa. Also, despite the heat exchanger, cold liquid can pass through it without mixing with hot liquid. In this way, heat is transferred without wasting. Heat exchangers are classified into three types of parallel, opposite or heterogeneous currents and cross-exchangers.

Piping equipment in the oil and gas industry

Used to transport gases and liquids inside the industrial unit. According to environmental conditions, they are made of steel, cast iron, copper, plastic, etc.

Storage tank in oil and gas industry equipment

Towers or tanks are large containers usually made of metal that are used to temporarily store various liquids and gases. Distillation and separation of raw materials and production of by-products such as gasoline, gas, bitumen, etc. are performed in this section using special equipment.

Industrial Valves

In the oil and gas industry, industrial valves are used to control the flow and control fluid pressure. Due to the fact that the materials inside the pipes and petrochemical equipment are dangerous for the environment and the staff of the place, it is necessary to ensure that the valves do not leak. Depending on the type of passing material, the material of the valves can be steel, steel, cast iron, etc. Valves are divided into two general types, manual and automatic.

Some of the main functions of industrial valves:

Controls the flow of liquids and gases and cuts off and on the flow when necessary.

Adjusts the pressure of liquids and gases as well as their passage.

Prevents the return of liquids and gases that have passed.

Pressure reducing device in oil and gas industry equipment

Materials such as gas, water vapor, liquids, etc. are used in refineries to release pressures. The presence of this device is essential to protect the operator and the equipment used. Because in the absence of this device, the pressure increases and in addition to damaging the equipment, it causes the system to shut down and in severe cases, there is a risk of death. For this reason, they are one of the most important equipments in the oil and gas industry.

Boiler

Uses chemical energy generated by burning oil or gas to convert water into steam. Used in petrochemical industries for such things as hot water production, dry steam, saturated steam or hot steam.

Furnace and heater

Used to heat gases or liquids. Fluid materials are reached to the desired temperature by this equipment.

Pipelines in oil and gas industry equipment

Another component of oil and gas industry equipment is pipelines, which act like blood vessels. Their job is to transport materials to refineries and other companies. Oil pipelines are used to transport petroleum products and gas pipelines are used to transport natural gas for domestic use.