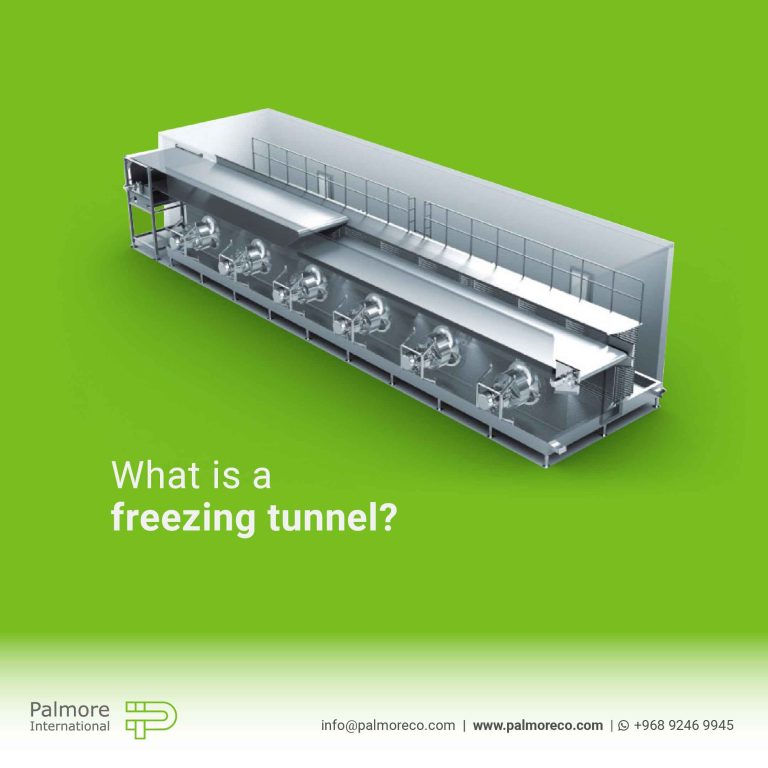

Quick freeze your products with a freezing tunnel

In a freezing tunnel, the product is cooled to a temperature between -30 and -60 degrees Celsius, allowing it to be cooled down to the proper temperature and pass through the maximum crystallization step as fast as possible.

Products that need to be frozen and stored for a long period of time are usually stored at -18 degrees Celsius or lower.

The following factors determine the final quality factors and life of frozen products:

1) The frozen product’s composition and nature

2) The product must be selected, transported, and prepared for freezing carefully

3) Method of Freezing

4) Product Storage Conditions

Freezing food is possible in a variety of ways. In some cases, freezing is done over time and slowly. In some conditions food requires quick freezing. For this purpose, the freezing tunnel is very suitable. The basis of this system (which is in fact a type of industrial refrigerator), is the indirect contact with the substance through the cold air flow, so by passing the cold air flow, the heat transfer phenomenon occurs in a compulsory place. Which increases the temperature reduction rate and leads to freezing of the material. The high speed of freezing in this method is very important; Because the quality and health of food tissue depends on the freezing time. When freezing is done at a low pace, ice crystals form in the food tissue and cause tissue destruction; With increasing the freezing speed, ice crystals become smaller and the tissue, appearance and taste of the food will be maintained.

Types of freezing tunnel

Freezing tunnels have different types based on performance needed. In these various types we can mention minus, contact, conveyor etc. In the minute types, cold air is frozen by passing through the products. In contact types, materials are intermediate between the substances and pass through the conveyor belt within the freezer. In a contact type, sometimes direct contact with liquid nitrogen is used. IGF is also a type of freezing tunnel in which the internal temperature of the material occurs less than two hours of critical temperature and very rapid freezing happens, which is done with increasing gas passage.

Advantages and Disadvantages

In this section, the freezing tunnel article is turned into the advantages and disadvantages of this system. Some advantages of freezing tunnel are:

Ability to freeze the product in short time

Preventing the collapse of cells and maintaining food tissue

Preventing the growth of bacteria and corruption

Quick Freezing and saving time

Require less manpower because of its automatic parts

Also you can read more:

Everything you need to know about refrigeration compressor

Freezing tunnel design

In this section, we will be talking about the design of freezing tunnels and its fundamental and essentials. In the field of design and construction of freezing tunnels, its capacity is the most important factor. Freezing tunnel uses equipment like compressors, evaporators, expansion tap, condenser, power boards and insulation in order to freeze food in high volumes and at high speed. The tunnel capacity is actually the amount of products that are cooled at a certain time to the desired temperature. Design calculations are based on the type of products that you want to freeze, substance, freezing temperature, and freezing time. In the design of freezing tunnels, you should be careful to reduce the time of freezing; Because reducing time preserves the main tissue of food. With increasing freezing time, the frozen surface of products and the ice on them acts as insulation and prevents the freezing within the product.

A variety of refrigerants such as Freon and Ammonia can be used in freezing tunnels. the volume of the devices in the presence of ammonia refrigerant can be reduced, due to the thermodynamic properties of ammonia. Using ammonia as a refrigerant may cause some problems such as oil return (due to the higher density of oil rather than ammonia) and the function of expansion tap with high superheat, which leads to an increase in the temperature of the compressor. So due to these problems using ammonia as a refrigerant is not a good idea.

In the freezing tunnels, the roof is embedded to circulate cold air flow. The air flow rate should be very high to increase the heat transfer rate. The freezing tunnel doors are composed of special screws for working in high pressure and in a variety of PVC, stainless steel or polyester and composed of aluminum insulation and special gaskets for maintaining temperature and local control to embed the control glass.

Palmore is one of the leading companies for the supply & installation of cold rooms & cold warehouses all over Oman and GCC. Offering a wide range of cold rooms & cold warehouses for commercial use, we supply to the various types of industries who are in need of cold rooms according to their customized design. We focus on customer requirements to reduce energy consumption and ever more stringent food safety regulations.