Types of cold room door

Cold room door is one of the most important parts for preserving the materials inside. One of the main steps in designing Cold rooms is choosing the door according to its type. In fact, doors are the most effective factor in the energy consumption of the cold storage through air exchange due to its relationship with the outside environment. The number of openings and closing of the door due to the increase of outside air infiltration into the indoor environment, makes the door system more functional and can increase energy consumption by up to 50%, so using a standard and appropriate door has a good effect on the optimal operation of Cold rooms. To keep the ingredients inside them, which are mostly edible, fresh and healthy.

Cold room doors are produced in the following types:

Hinged door

Sliding doors

Vertical doors

Semi-insulating doors

Insulating doors

Hinged cold room door

This door is known as the most widely used door from the past to the present due to its simple mechanism. The simplicity of the mechanism, low price and thus reducing the cost of construction of the cold storage, long life and ease of use and installation, are the advantages of the hinged cold storage door. The hinged door is more suitable for cold storages with low traffic due to the high heat loss it creates when opening and closing.

Also, due to the fact that the support of these doors is located on one side, this type of refrigeration door can not be used in large dimensions. Because as the door enlarges, a lot of pressure is applied to the hinges and also a lot of space will be needed to open and close the door. For this reason, they are made in standard dimensions to fit its components. So that there is no problem during use.

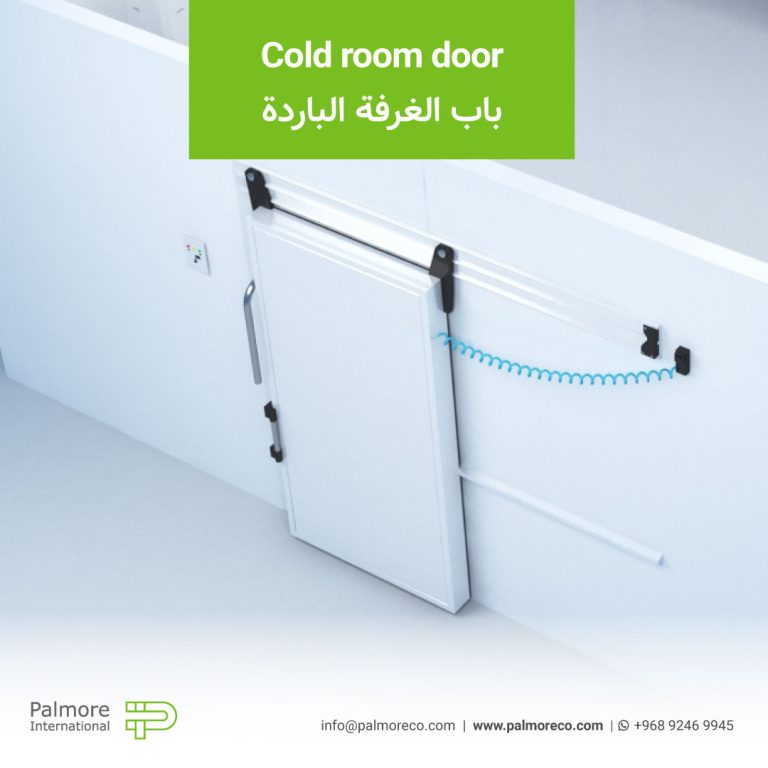

Sliding cold room door

This door is suitable for frequent opening and closing. The reason for this is low waste and low air exchange when opening and closing the door. In large cold rooms, sliding doors are motorized, which increases the speed of opening and closing and eliminates the need for manual force to open and close. Also, sliding doors need less space to open and close and are very suitable for large dimensions. These doors are used in many parts due to their different features.

Advantages of sliding cold room doors:

reliability and durability − Both of these features are essential for intensive use.

There’s no “dead zone” before entering − convenience in the confined spaces, corridors.

An insulating seal and clamping device. Due to the construction of the rail and the pressure roller, the door seals automatically under its own weight.

It makes using large doorways possible.

Atmospheric control sliding cold room door

Atmospheric control cold room door is suitable for cold stores where special and oxygen sensitive fruits and vegetables are stored. In the sense that this type of door prevents the infiltration of outside air into the inside so that the percentage of oxygen in the air inside the cold room does not increase and thus increase the life of food. These types of doors, due to their sensitivity, are usually made of sliding type. In addition to comfort when opening and closing, it has higher strength and efficiency.

Vertical doors

The panel of the door rises in this version, which is convenient when there is not enough room to open the sliding gates. Due to their difficulty in opening manually, such gates are usually operated by electric motors.

Disadvantages of the vertical cold room doors:

The tightest feeling;

It is more expensive than collapsible gates.

Cold room door fittings

Cold room door fittings are very diverse and have a variety of goods. Fittings are needed to install refrigeration doors. Hinges, locks, and handles are examples of fittings. Fittings are one of the important parts of such doors. The type of seal and their resistance to temperature changes, the type of lock and nut and… are among the most important factors. Therefore, the use of fittings and of course their quality is very important. Because they affect the final quality of our doors. For this reason, one of the most important parts to check the quality of doors is the quality of fittings. Handles and locks in between are among the important parts of the door. Which must also be resistant to temperature changes.

Cold room door hinge

The use of hinges causes the refrigeration doors to open and close. One of the most important door fittings in cold stores is the use of hinges. One of the functions of the hinges is to support the weight of the door. Failure to use proper and quality hinges may cause personal and financial damage. Because the right hinge must be able to withstand the weight of the door. While not changing with temperature changes and quality reduction. The number of hinges in proportion to the dimensions of the door is another important factor in this regard.

Cold room door lock

For safety, they install locks on the glass doors of the cold storage, which have different types. Standard alloy is very important in making locks because not using it will cause the gears to fail. One of the most important parts of refrigeration doors is the type of lock. These tools should be such that they do not have problems with lowering the temperature and freezing. Also, ease of opening and closing and no environmental effects on it are among the important factors in locks. The quality of the lock can also guarantee the final quality of your door.